3D Printing

Additive Manufacturing with our HP JetFusion 4200 printer

Upload your 3D-model and get an instant quote

Parts available in „natural“ and „black“

Produced in Rheinbach / Germany

Order your parts

Upload your 3D-files and see instant pricing.

Add your desired quantity to the basket and submit your order.

Make a secure payment

Production

After a check of your 3D-files we will start production at our own production facility.

Your parts will be depowdered and optionally dyed .

Delivery

We hand over your parts to the shipping partner

Printing Information

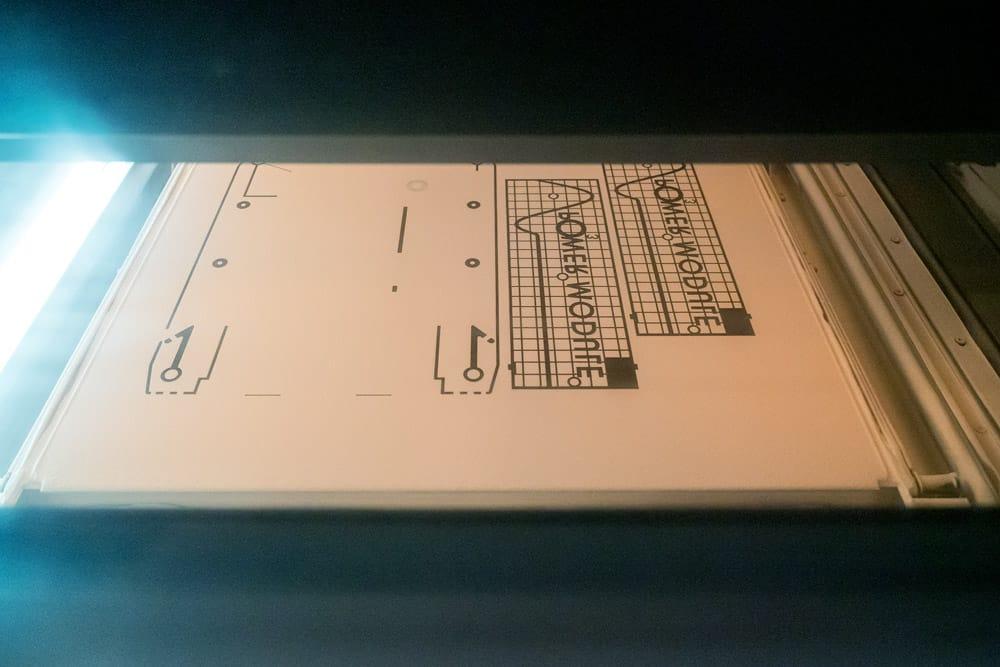

HP JetFusion 4200

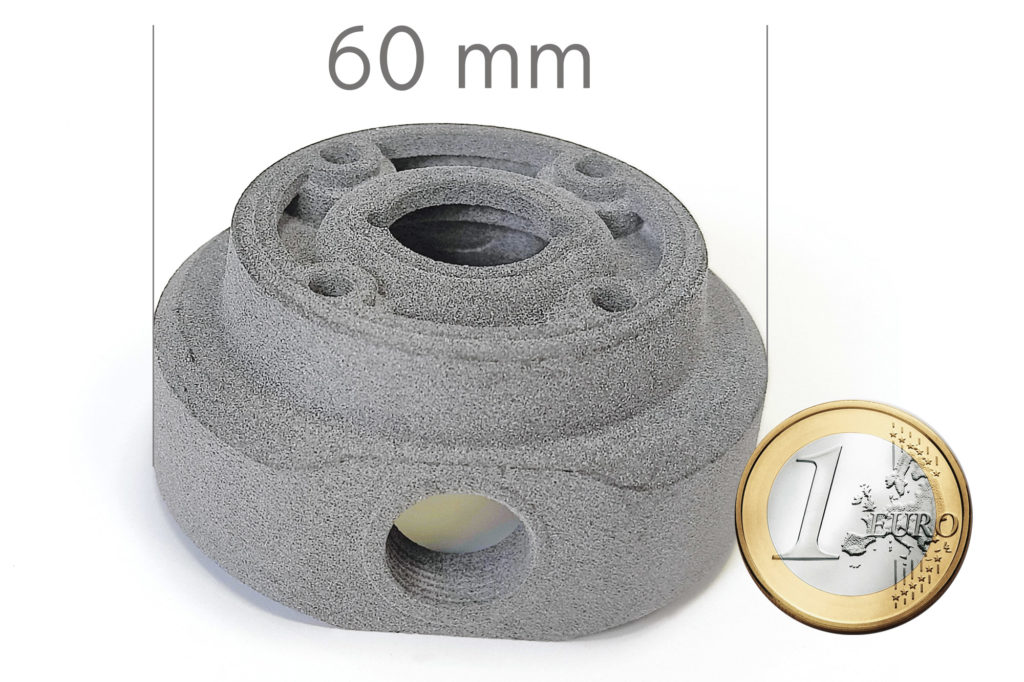

The HP JetFusion is a powderbed-based manufacturing process. Multiple parts can be printed simultaneously in a short production-cycle. The parts are made of PA12 plastic powder with a blasted surface appearance. PA12 parts are very strong and black in the inside. The surface is naturally grey after printing with no additional dyeing.

Part orientation

The part orientation is done automatically by our software when your part is nested to the build process. Due to the powderbed-based process, no additionally support-structures are needed. You don’t need to think about the part orientation in your 3D-file.

Part finishing

All printed parts are depowdered in our automatic depowdering machine. Here the surplus powder is blasted from the solid part by glas beads. So you get a slightly rough surface almost without any visible layer lines.

After depowdering the parts have a grey surface. Optionally we dye your parts black with dyes from TCN.

Part design guidelines

Unit in 3D-file: mm (inch, m, cm , … not supported!)

File format: .stl (.3mf on request)

The maximum printable build volume is 360 x 260 x 360 mm.

The dimensional accuracy is +- 0,2 mm for parts up to 100 mm.

Small features should have a minimum size of 0,5 mm.

Walls should have a minimum thickness of 0,5 mm.

Assembled parts can be printed together with a spacing of approx. 0,5 – 0,7 mm.

Cavities should have a big enough opening and deep holes should be avoided for better access while depowdering.

Material Information

PA12

We use HP 3D HR PA 12 for printing.

PA12 is a thermoplastic material with outstanding mechanical properties. The final parts are solid, dimensionally stable, watertight and chemically resistant to oil, grease, aliphatic hydrocarbons and alkalis.

HP 3D HR PA 12 is certified for use with direct skin contact according to FDA and USP Class I-VI

TCN dyes

Optionally your parts are dyed black with TCN GTC 8211C black after depowdering. Therefore the parts are added to a bath with dissolved dye for several minutes, rinsed and dried.

Frequently Asked Questions